Pumps

Trinity has the facilities to overhaul, repair, refurbish, fabricate and manufacture a variety of pumps and pump components. Manufacturing of pump components is carried out by customer specification, drawings or by reverse engineering through customer provided samples. Commonly manufactured pump components include:

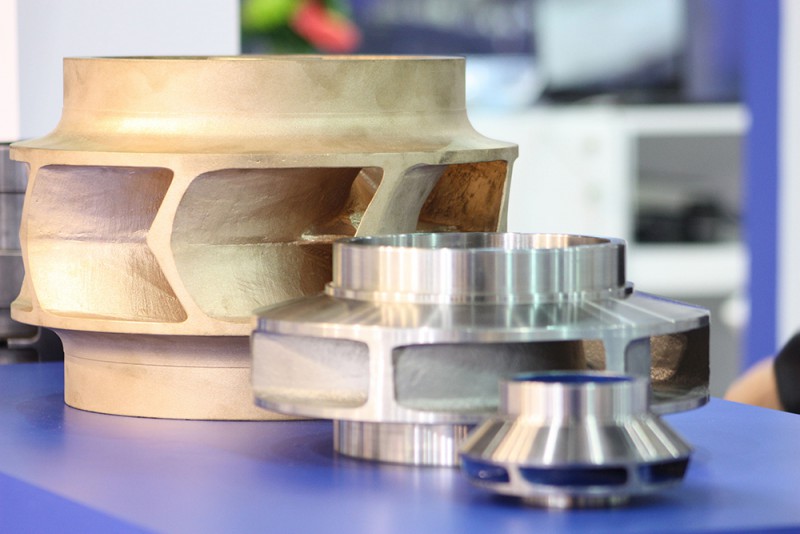

- Impellers

- Pump casings

- Pump shafts

- Diffusers

- Wear rings

- Couplings

- Sleeves

- White metal bearings

In addition to the above components Trinity also repairs the following components:

- Mud Pump Crank Shafts

- Mud Pump Connecting Rods

Trinity uses a variety of materials to manufacture pump components in the foundry such as alloy, stainless, duplex & super duplex steels, cast iron, ductile iron, bronze, aluminium bronze, phosphor bronze, nickel aluminium bronze, aluminium, inconel & monel among others. Trinity keeps stock of some of the commonly used materials for providing quick delivery times to customers. Moreover, our foundry & machine shop are equipped to take on single orders or large scale orders to attend to every type of order that our customers have.

For such components, specialized services such as protective coatings, surface treatment or heat treatment is carried out for improved life of the component. Additionally, Trinity has the capability to carry out dynamic balancing of the rotary components or their assemblies.

Trinity Holdings also has its own dewatering pump manufacturing facility. For more information on these products, please visit our Oasis Pumps company website at www.oasispumps.ae.

-

Graded Impellers

-

Pumps Parts