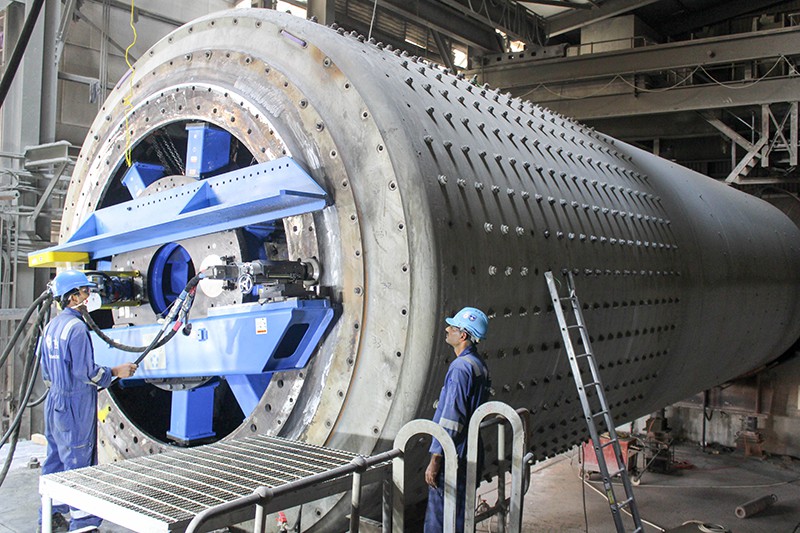

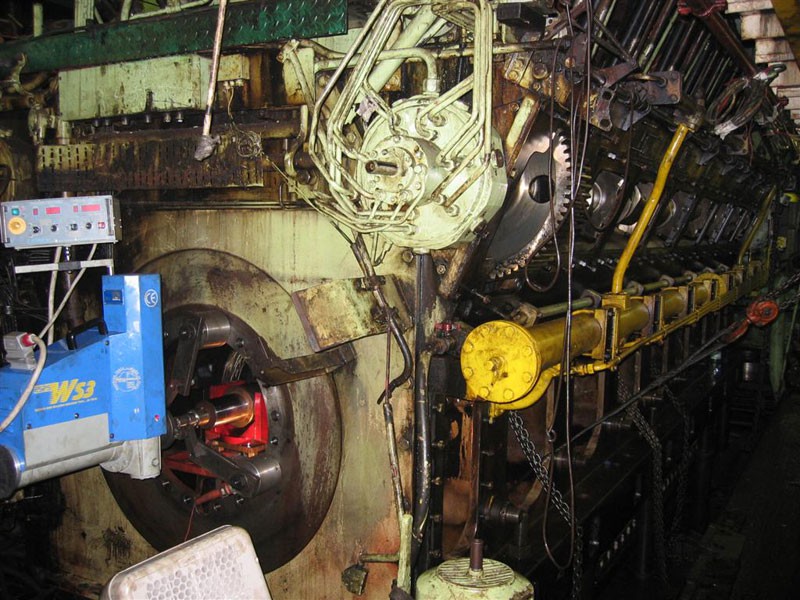

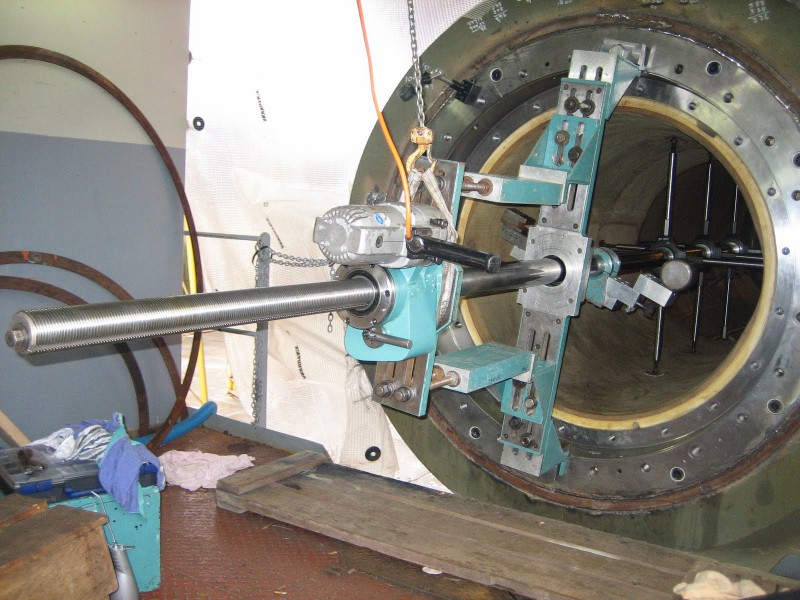

Insitu Services

Trinity offers a full range of insitu services around the clock, domestically and internationally. Insitu machining minimizes asset downtime and maximizes savings by eliminating costs associated with dis-assembly, removal, transportation and re-installation of machinery. Our range of insitu services include:

Line Boring Services

- Engine block main line

- Turbo casing

- Stern tubes

- Rudder bearings

- Cylinder liner seats & landing faces

Flange Facing (up to 8m)

- Pressure vessel flange faces

- Crane bases

- Mounting flange faces

General Insitu Services

- Metal stitching

- Stud removal – spark erosion/insitu drillin

- Welding

- Thermal Spray (Twin wire arc)

Milling Services

- Engine bed plates

- Foundations – covering large lengths and breadths

- Crane rail tracks

Laser Alignment

- Engine mainline bore

- Stern tubes

- Compressors

- Insitu crankshaft grinding

- Insitu brush plating

- Overhauling

- Shaft outer diameter turning[/bulletlist]

Trinity caters to the insitu needs of many industries such as oil & gas, marine, energy, cement, and crushers. The insitu team is trained to achieve the high precision results when working with components such as flanges, stern tubes, crane bases, cylinder liners, engine blocks and bearing journals. Trinity has dedicated teams to attend to insitu requirements. Trinity’s experienced and skilled engineers have the capability to design custom made machine tools, fixtures and associated machinery to suit on site requirements. Repeatedly, the insitu team has demonstrated their ability to provide quality service to their customers, which has allowed Trinity to build a strong customer base.

-

Insitu Services

-

Insitu Services

-

Insitu Services

-

Insitu Services