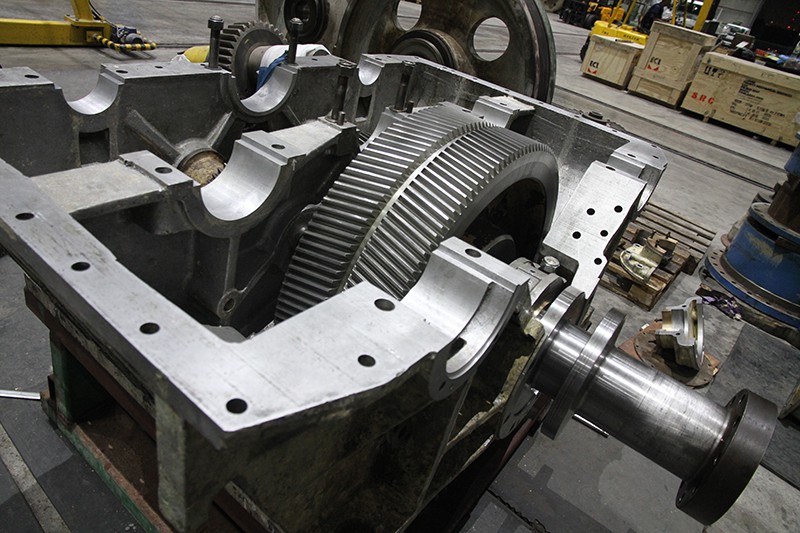

Gears, Gearboxes and Sprockets

Trinity has the expertise to overhaul and machine gear box assemblies of various types. After complete tear down, each component is inspected and a report is provided to the customer identifying all parts that need to be replaced or repaired. Trinity has the facilities to manufacture gears, sprockets & splines of various types by reverse engineering from customer supplied samples or drawings. Over the years, Trinity has manufactured gears used in crane gear boxes, sprockets and automotive engines among other assemblies. We are capable of working with gear boxes of various shapes and sizes.

Our in-house machine shop is equipped with gear hobbing, gear shaping, milling, slotting and tooth grinding machines operated by skilled technicians manufacturing high quality gears. Trinity also has the facility to create specialized tools for non-standard gears which cannot be easily manufactured. Commonly manufactured gears are mentioned below:

- Spur gears

- Helical gears

- Bevel gears

- Spiral bevel gears (Spherical)

- Planetary gears

- Splines

- Sprockets

Trinity has an in-house heat treatment facility for induction hardening, annealing, carburizing, nitriding, hardening and tempering to improve surface properties of gears. Our fast and high quality service provides a great alternative to purchasing original parts from OEMs as we can help you save time and money without compromising on quality.

Furthermore, with an in-house foundry, Trinity can cast and machine gearboxes, gearbox covers and other components of a gear box.

-

Gears

-

Sprockets

-

Sprockets

-

Gearbox