Welding and Fabrication

To complement the overhauling and fitting section, Trinity has a fully equipped and trained team for welding and fabrication. We provide various types of welding procedures and are able to design and fabricate components of various shapes and sizes. In the market, Trinity is known to take on and successfully complete challenging jobs.

Welding

Trinity’s welding shop has various welding processes to cater to different applications and materials, these processes include:

- Tungsten inert gas (TIG) welding

- Metal inert gas (MIG) welding

- Electric arc welding

- Submerged arc welding (SAW)

- Fusion welding

- Plasma transferred arc (PTA)

Plasma Transferred Arc

Plasma Transferred Arc (PTA) is a process that creates a small heat affected zone (HAZ) with a short arc and thus transfers less heat to the component. This produces high quality deposits with optimal protection, minimal dilution and deformation of the base material. Components such as exhaust valve spindles & seats, gate valves, butterfly valves, mechanical seals and extruder screws are repaired with Stellite, SS, Ni base alloys using PTA.

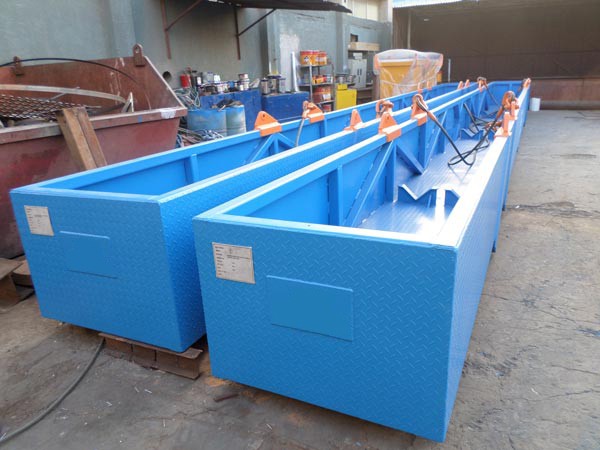

Fabrication

Our trained and qualified welders have procedure approvals for fabricating numerous different materials. Trinity’s fabrication yard commonly fabricates components such as gate valves, dredger parts, buckets, off-shore baskets, cranes, containers and silos. The fabrication team is able to complete jobs as per:

- Drawings provided by the customer

- Reverse engineering fabricated components

- Repairing broken or cracked components

More about welding and fabrication

The welding and fabrication department caters to a various industries and services numerous different products including but not limited to:

- Transport & earthmoving: Excavator buckets, boom and track pads.

- Dredging: Dredger structures, suction doors and gate valves.

- Oil & gas: Off-shore baskets, containers and storage tanks.

- Desalination: Storage tanks in structural steel & stainless steel.

- Power: Piping and ducting works (water, fuel and exhaust).

- Cement/crusher: modification of equipment and plants.

- Marine: Piston crowns, exhaust valve spindles & seats and cylinder covers.

- Cranes: Overhead, gantries and semi gantries

-

Welding and Fabrication

-

Welding and Fabrication

-

Welding and Fabrication

-

Welding and Fabrication