Ancillary Equipment and Components

Trinity offers repair and/or manufacturing services for various ancillary equipment and components related to oil tools.

Mud pumps

- Reconditioning of casing, crankshaft and connecting rods

- Repair and manufacturing of liners, valve covers, wear plates, fluid ends, suction & discharge modules, stuffing boxes, cross heads and piston rods.

BOP hoists

- Complete overhauling of BOP Hoists with re-certification

- Manufacturing of all load bearing and rotary components

- Reverse engineering to fabricate the entire assembly.

Draw works

- Overhauling of draw works and repairing & manufacturing of individual components

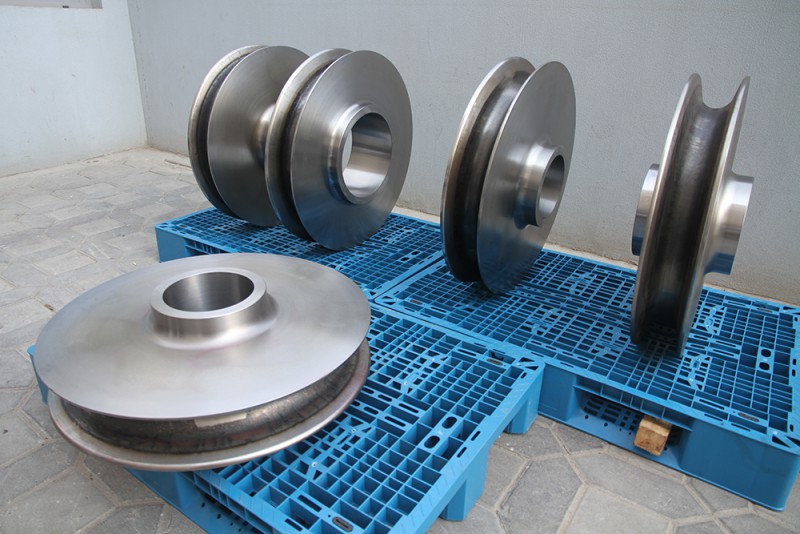

Travelling blocks

- Snatch blocks - overhauling, repairing and manufacturing of individual components

- Sheaves

Crown blocks

- Overhauling of crown block assemblies and repairing & manufacturing of individual components

Tongs

- Overhauling of tongs

- Repair and manufacturing of components

- Manufacturing of tong dyes

Elevator

- Overhauling of elevators and repairing & manufacturing of individual components

Rotary Tables

- Complete fabrication of rotary tables with all components as per customer designs

- Overhaul and repair of rotary table and manufacture individual components

Rotary Bushings

- Master bushings

- Casing bushings

- Kelly roller bushings

Offshore units

-

Skips or Skids

- Fabrication of skips for hydraulic benches, motors, compressors as per customer design.

-

Containers

- Fabrication or supply of standard containers for storage

- Customer based modification for office space/work space for offshore locations

-

Winches

- Fabrication & machining of various types of winch assemblies and its individual components including sprockets, shafts and winch drums

- Overhauling, repair and reconditioning of complete winch assemblies including repair of its various components.

-

Baskets

- Design, fabrication and modification of offshore baskets of various sizes and load capacities for safe transportation of tools

-

Mechanical components - Drive train, brake and spooling assemblies

- Manufacturing of various components such as pins, clevis, screw rods, bearing adaptors and brackets, sprockets, torque adaptors, brake bands, rudders, anchors, supports, covers, spooling arms, axles, adjustment and alignment rods.

Slips

- Manufacturing of all types of rotary, casing pipe and drill collar slips as per customer specifications

- Special heat treatment through QPQ and Induction Hardening processes

Swivel Joints

- Overhauling of Swivel joints and repairing by welding and machining of ball seating areas, seal areas, replacing of damaged consumables and pressure testing

-

Ancillary Equipment

-

Ancillary Equipment